Vacuum infusion - production of durable laminates

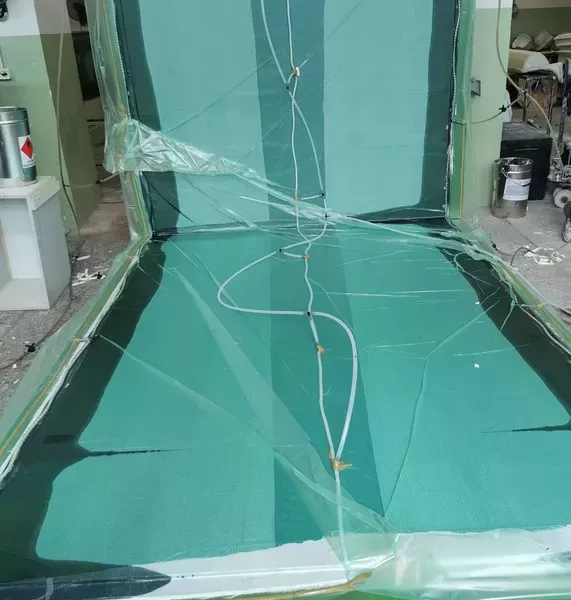

We are a manufacturer of laminates using the infusion method, a technologically advanced process that allows obtaining a high level of strength and excellent mechanical parameters. This method involves laying dry reinforcement in a form covered with gelcoat. Then, a mesh should be placed to improve the flow of resin, and finally, a delamination fabric should be placed. All this is sealed in a sealed vacuum bag. After the air is pumped out, the resin is injected. The pressure difference causes the resin to be distributed evenly throughout the mould.

What industries use infusion laminates?

Infusion is a technique used in the production of advanced composites, such as composite laminates used in the aviation, automotive, construction and other industries that require lightweight, durable and structurally advanced materials.

Laminate composites are being used for, among others, the production of washbasin troughs, camper-vans bodies, shower cabins for social containers, shower trays, caravan cabins, as well as engine housings for various vehicles and machines, automotive canopies, etc. The infusion method is also used in the production of sailing yachts, motor boats and wind turbine blades.

Advantages of laminate production using infusion technology

Infusion technology is frequently used in the production of laminates. Thanks to it, it is possible to obtain a high level of strength and accelerate the entire production process of large-sized elements. Moreover, the infusion allows us to:

- reduce the costs of laminate production;

- maintain a repeatable product quality;

- production of laminates with constant wall thickness;

- production of laminates with a perfect connection;

- selection of various resins and fabrics.

An important advantage of this method is the reduction of emissions of harmful chemical compounds. Manufacturing the product using infusion means that styrene emissions are as much as ten times lower than in the case of traditional technology.

We are an experienced and reliable laminate manufacturer that focuses on the development and use of modern technologies, including the infusion method. If you are interested in our offer, we invite you contact the company.